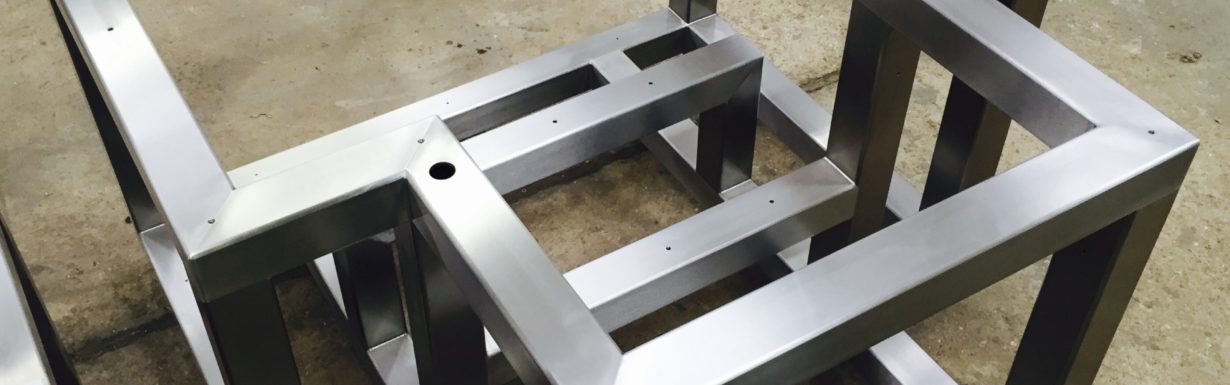

Stainless Steel Fabrication

One of the most common industrial alloys, stainless steel is highly machinable and adaptable to custom applications. The types of processes, transformations, and finishes it undergoes are as varied and unique as its applications.

Stainless steel fabricators can transform sheet metal with processes such as:

- Bending

- Cutting

- Press and roll forming

- Joining

- Mechanical working

- Annealing

- Drawing

- Folding

- Anodizing

- Electrical discharge machining

- Welding

- Riveting

- Brazing

- Stamping

- Punching

Once a sheet of metal has been transformed into a three-dimensional piece, it can be finished with paint, powder coatings, silk screening, and other specialized surface treatments. Most specialty manufacturers will offer a full array of processing services, all with their own process qualities, finishing options, and unique results.

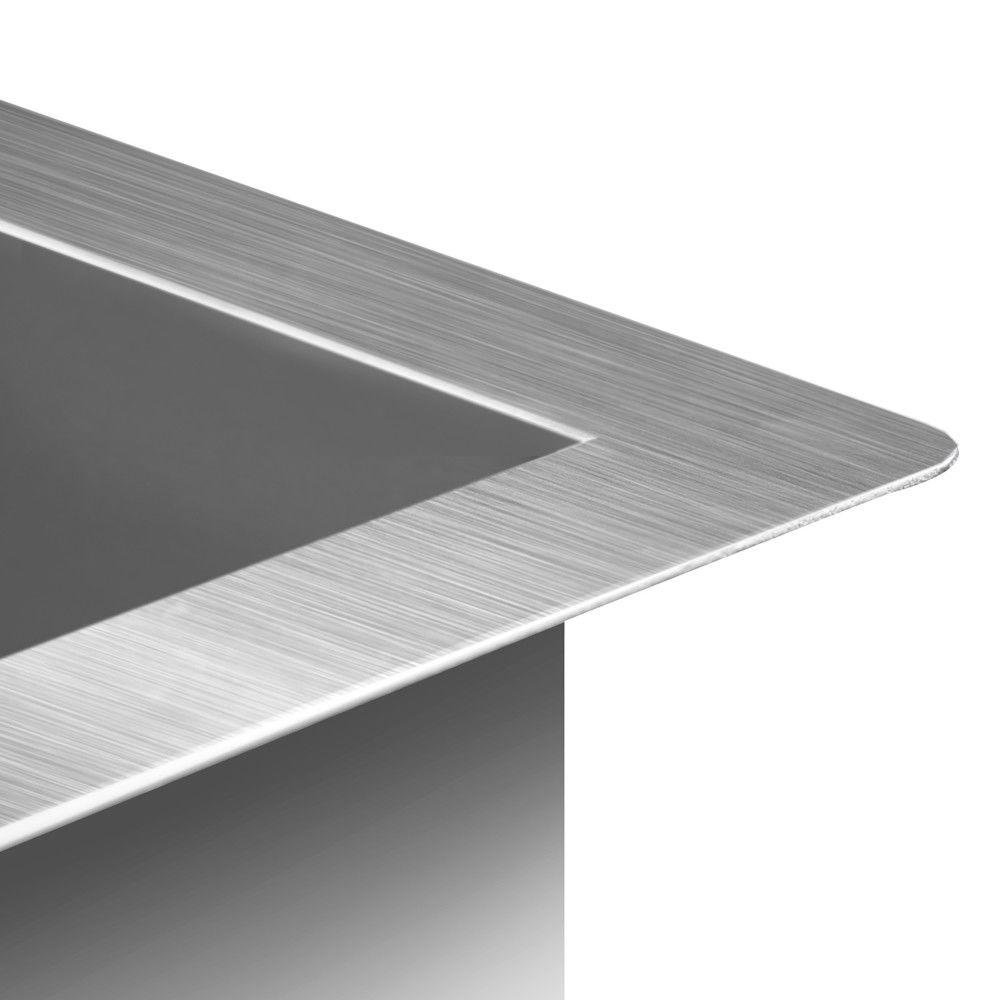

One of the most widely known steel alloys, stainless steel is also known as inox steel or inox. It is always made up of a minimum of 10.5% chromium, which gives it a number of specific properties.

Unlike standard steel, stainless does not easily rust, corrode, or otherwise stain with water. Different surface finishes and varying grades are increasingly corrosion resistant, and some will perform better than others when exposed to high-salinity, low air circulation, and other such demanding environments.