Abrasive Performance Secrets: Why 3M Leads in Dubai

When it comes to abrasives, not all products are created equal. In Dubai’s competitive industrial landscape, professionals choose 3M for their unmatched quality, innovation, and reliability.

In this post, we reveal the performance secrets that make 3M a leader in abrasives and why it’s the go-to brand for metalworking, construction, and manufacturing projects across Dubai.

The Technology Behind 3M Abrasives

3M invests heavily in research and development to produce abrasive products that deliver superior results. Their secret?

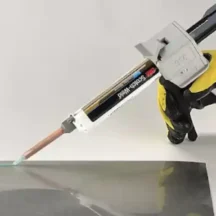

Precision-Shaped Grain

3M’s Cubitron™ II abrasives feature ceramic grains precisely shaped to slice through metal quickly and cleanly, unlike traditional crushed abrasives.

Structured Abrasive Surfaces

Products like 3M Trizact use three-dimensional abrasive patterns that maintain a consistent finish and reduce rework.

Durable Backing Materials

Strong, flexible backing ensures abrasives last longer even under tough conditions.

Why Dubai Professionals Rely on 3M Abrasives

Dubai’s industries demand speed, quality, and safety. Here’s why 3M stands out:

- Faster Cutting and Grinding: 3M abrasives reduce job time, helping projects stay on schedule.

- Longer Tool Life: Durable products mean fewer replacements and lower costs.

- Cleaner Finishes: Consistent performance produces smooth surfaces with less effort.

- Versatility Across Applications: From shipbuilding to pipeline welding and automotive repair, 3M offers solutions for many tasks.

How to Maximize Abrasive Performance

To get the most from 3M abrasives:

- Use the right product for your material and task

- Maintain proper tool speed and pressure

- Regularly inspect abrasives for wear and replace as needed

- Follow safety guidelines to protect yourself and equipment

Frequently Asked Questions (FAQs)

Q1: Are 3M abrasives suitable for all metals?

Yes, 3M offers products designed for carbon steel, stainless steel, aluminum, and more

Q2: How do I know when to replace my abrasive discs or belts?

Replace when cutting slows or the abrasive surface looks worn or damaged.

Q3: Can I use 3M abrasives on handheld grinders?

Yes, many 3M abrasives are designed for handheld tools—just check compatibility.

Q4: Do 3M abrasives work well in Dubai’s climate?

Absolutely. Their durable construction withstands heat, dust, and harsh environments.

Ready to Experience 3M Abrasive Excellence in Dubai?

At Junco LLC, we provide genuine 3M abrasive products and expert support to keep your projects running smoothly.

Contact us today to find the perfect abrasive solution for your needs.