Cubitron 3: A Must-Have for Heavy Machine Builders

Heavy machine building demands tools that can keep up with tough materials and tight deadlines. When it comes to abrasives, Cubitron 3 stands out as the industry favorite for those who need speed, durability, and precision.

In this post, we’ll explain why Cubitron 3 is a must-have for heavy machine builders and how it helps us deliver superior results every time.

What Is Cubitron 3?

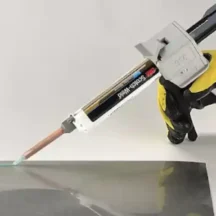

Cubitron 3 is 3M’s latest abrasive technology featuring precision-shaped ceramic grains designed to cut faster and last longer than traditional abrasives. It’s engineered for heavy-duty grinding tasks where performance matters most.

Why Heavy Machine Builders Trust Cubitron 3

Heavy machine components are often large, thick, and made from tough metals. Cubitron 3 meets these challenges by offering:

Faster Cutting Speeds

Precision grains slice through metal quickly, reducing job time.

Extended Abrasive Life

Durable design means fewer wheel changes and lower costs.

Cooler Operation

Reduced heat generation protects both the tool and workpiece.

Superior Surface Finish

Achieve smooth, consistent finishes ready for assembly or coating.

Key Applications for Cubitron 3 in Machine Building

- Weld preparation and removal

- Surface grinding and blending

- Deburring sharp edges

- Finishing components before painting or coating

Tips for Getting the Best Results

- Use the right grit for your material and task

- Match grinder speed to wheel specifications

- Apply light, steady pressure and avoid forcing the tool

- Replace wheels when performance declines to maintain quality

FAQs About Cubitron 3

Q1: Is Cubitron 3 suitable for all metals?

Yes, it works well on carbon steel, stainless steel, and alloys common in heavy machinery.

Q2: How does Cubitron 3 compare to Cubitron II?

Cubitron 3 offers improved grain design for even faster cutting and longer life.

Q3: Can I use Cubitron 3 on handheld grinders?

Yes, but always check compatibility with your tool specifications.

Q4: Does Cubitron 3 reduce operator fatigue?

Yes, it requires less pressure for cutting, making work easier and safer.

Ready to Upgrade Your Abrasive Tools?

At Junco LLC, we stock genuine Cubitron 3 products and provide expert advice to help you get the most out of your grinding tasks.

Contact us today to learn more and equip your workshop with Cubitron 3 abrasives.